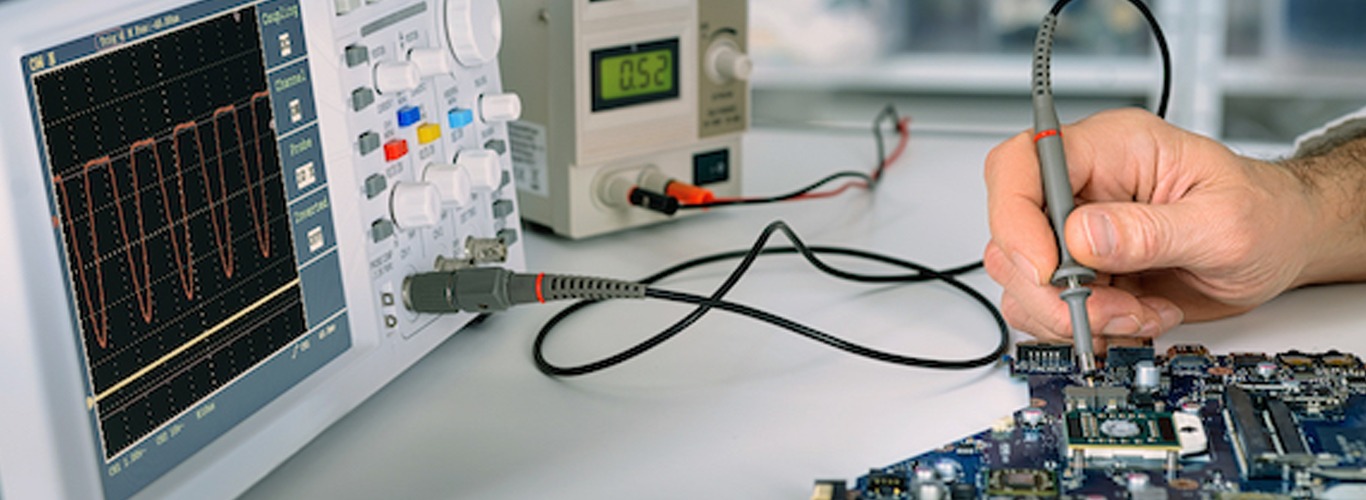

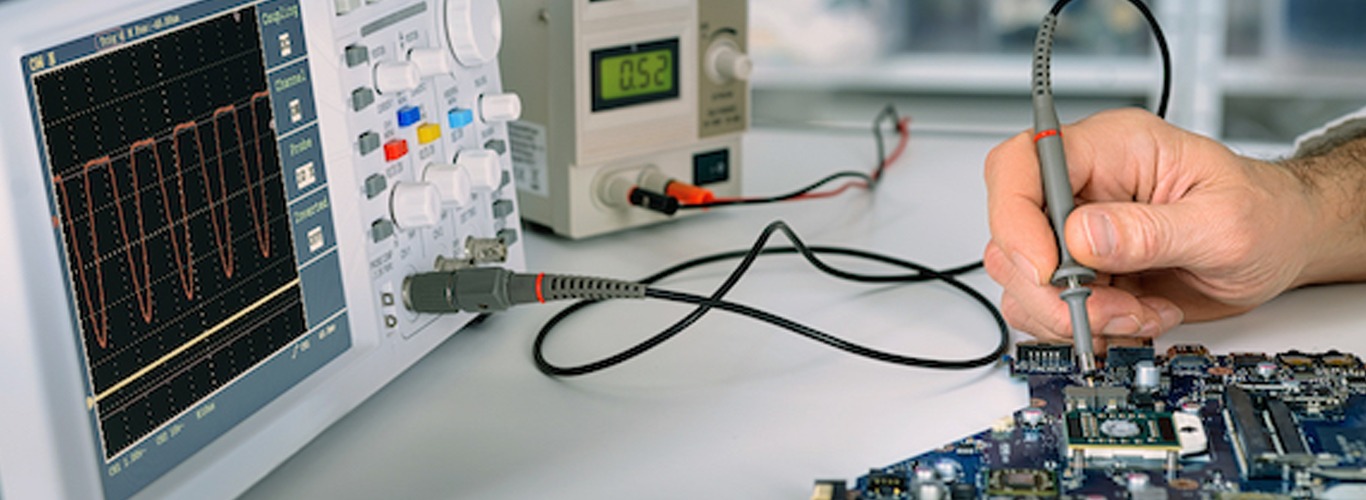

The importance of medical equipment maintenance

Posted on 01/06/2025

Medical equipment that is not properly maintained can pose serious risks to patient safety. Regular maintenance can help ensure that the equipment is functioning properly and that there are no malfunctions or errors that could put patients at risk. Maintaining medical equipment can also save money in the long run by preventing costly breakdowns and repairs. Regular maintenance can also extend the lifespan of the equipment, meaning that it won't need to be replaced as frequently. Many healthcare facilities are required by law to ensure that their medical equipment is properly maintained and calibrated.

Properly maintained equipment is more likely to function efficiently and effectively, which can improve the overall quality of care that patients receive. This can lead to better outcomes and increased patient satisfaction. Well-maintained medical equipment can operate at peak efficiency, reducing the risk of errors and improving patient care. This can be especially important in busy healthcare environments where equipment is in constant use.

Regular maintenance can also provide an opportunity for staff education and training. By involving staff in the maintenance process, they can gain a better understanding of how the equipment works and how to identify potential issues before they become major problems.

Tips to maintain medical equipment efficiently

1. Follow manufacturer guidelines: The manufacturer of the equipment provides guidelines on how to use and maintain the equipment. It's essential to follow these guidelines carefully to ensure that you are using and maintaining the equipment correctly.

2. Regular cleaning and disinfecting: Regular cleaning and disinfecting are essential for medical equipment to prevent the spread of infection. Use recommended cleaning agents and follow the instructions for use.

3. Perform regular inspections: Regular inspections help to identify any issues with the equipment before they become major problems. Inspect the equipment before and after each use, and schedule routine inspections with a qualified service technician.

4. Keep records: Keep a detailed record of all maintenance and repairs performed on the equipment. This record will help you identify any recurring issues and ensure that you are keeping up with the equipment's maintenance needs.

5. Train staff: Ensure that all staff members who use or maintain the equipment are properly trained. This training should cover the proper use and maintenance of the equipment and safety precautions.

Cleaning and disinfection of medical equipment

The first step in cleaning medical equipment is to remove visible dirt and debris using soap and water or a cleaning solution recommended by the manufacturer. Make sure to use a soft cloth or sponge to avoid scratching the equipment surface. After cleaning, rinse the equipment thoroughly with clean water to remove any residue.

Disinfecting medical equipment is necessary to kill harmful microorganisms that can cause infection. Disinfectants recommended by the manufacturer or regulatory agencies should be used

Some medical equipment may require sterilization, especially if it comes into contact with bodily fluids or is used for invasive procedures

Make sure to use appropriate PPE such as gloves, gowns, and masks during cleaning and disinfection is essential to protect healthcare workers and prevent the spread of infection.

How to establish an effective medical equipment maintenance program

1. Identify equipment: The first step is to identify all the medical equipment in your facility. Create a comprehensive list that includes the type of equipment, location, and manufacturer.

2. Develop maintenance schedules: Once you have identified the equipment, determine the frequency and type of maintenance required for each piece of equipment. This information can be found in the manufacturer's recommendations, regulatory guidelines, and best practices. Create a maintenance schedule that includes regular inspections, cleaning, disinfection, calibration, and repairs.

3. Assign responsibilities: Determine who will be responsible for each aspect of the maintenance program, such as inspections, repairs, and record-keeping. Ensure that staff members are trained and competent to perform their assigned tasks

4. Review and update the program: Regularly review the maintenance program to ensure that it remains effective and up-to-date. Make any necessary changes based on new equipment, regulations, or best practices.

5. Invest in technology: Consider using technology such as Computerized Maintenance Management Systems (CMMS) to automate maintenance schedules, track equipment inventory, and monitor equipment performance.